TASK 1:

Question: The diagram shows the manufacturing process of olive oil of different grades.

ANSWER:

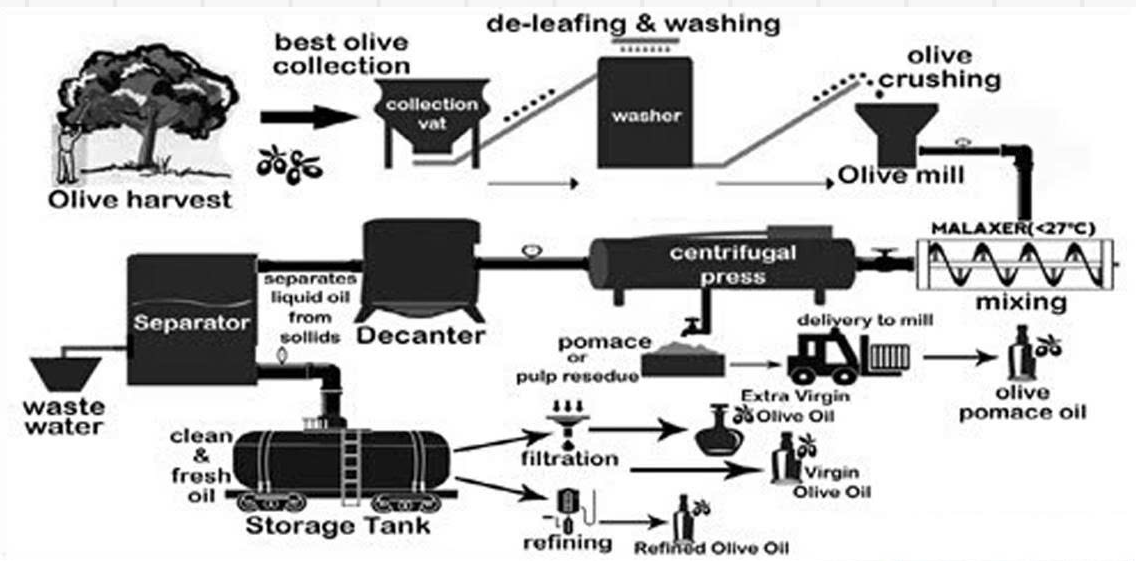

The diagram illustrates the stages involved in the production of different grades of olive oil from harvested olives. The process includes a range of mechanical procedures from initial treatment to final refinement.

Overall, it can be seen that olive oil manufacturing is a multi-step procedure beginning with the collection and preparation of olives, followed by the extraction and separation of oil, before the product is stored and refined into various grades. Notably, while higher-quality oils are ready after extraction, lower-grade oil requires additional processing.

At the initial stage of the process, ripe olives are collected from trees and transferred to a collection vat, where they are sorted to remove damaged fruit. They are then passed through a de-leafing and washing unit to eliminate leaves, dirt and other unwanted materials. After cleaning, the olives are crushed in an olive mill to form a coarse paste, which is subsequently transferred to a malaxer and processed at around 27°C, a temperature that facilitates the release of oil.

Once this preparation is complete, the paste is pumped into a centrifugal press, which separates the liquid component from solid waste, known as pomace. The extracted liquid is further processed in a decanter to separate olive oil from waste water, while the leftover solids are removed. The oil is then channelled into storage tanks, where it is categorised into several grades, including extra virgin, virgin and olive pomace oil. Although the high-grade oils are ready for consumption at this stage, lower-quality oil undergoes an additional filtration and refining procedure before being marketed as refined olive oil.(204 words)